Introduction:

Polypropylene (PP) sheets are versatile materials known for their durability, chemical resistance, and wide range of applications across industries. The manufacturers of PP sheets play a pivotal role in ensuring quality, innovation, and accessibility in the production of these essential materials. In this guide, we'll delve into the realm of PP sheet manufacturing Singhal Industries - Manufacturer of Flexible Packaging Product, explore leading manufacturers, and shed light on pricing and availability.

1. Importance of Polypropylene Sheets:

Versatility:

- PP sheets find applications in industries such as packaging, automotive, construction, agriculture, and healthcare, owing to their lightweight nature, chemical resistance, and ease of fabrication.

Durability:

- PP sheets are renowned for their strength, impact resistance, and dimensional stability, making them ideal for demanding environments and applications that require robust materials.

Customization:

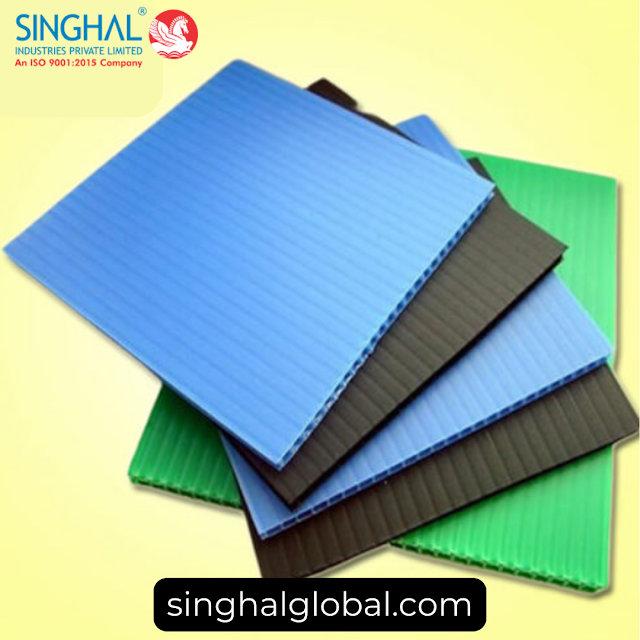

- Leading Polypropylene sheet manufacturers offer customization options in terms of sheet thickness, size, color, surface finish, and additives, allowing clients to tailor the sheets to their specific requirements.

2. Leading Polypropylene Sheet Manufacturers:

Company A:

- With decades of experience and a commitment to innovation, Company A is a leading manufacturer of PP sheets, offering a diverse range of products for industrial, commercial, and consumer applications.

- Leveraging advanced manufacturing technologies and stringent quality control processes, Company A ensures that its PP sheets meet the highest standards of performance, reliability, and consistency.

Company B:

- Recognized for its expertise in polymer science and engineering, Company B specializes in producing high-performance PP sheets with superior properties and functionality.

- Committed to sustainability and environmental responsibility, Company B employs eco-friendly manufacturing practices and materials, minimizing its carbon footprint while delivering innovative solutions to its clients.

3. PP Sheet Roll and Pricing:

PP Sheet Roll:

- PP sheets are available in rolls or sheets, with roll formats offering convenience and flexibility for large-scale production processes, packaging applications, and custom fabrication.

Pricing Considerations:

- The PP sheets price varies based on factors such as sheet thickness, size, quantity ordered, customization options, and prevailing market conditions.

- Bulk orders and long-term contracts may qualify for volume discounts or special pricing arrangements, offering cost savings for businesses with high-volume sheet requirements.

Conclusion:

Polypropylene sheets are indispensable materials in modern industries, valued for their versatility, durability, and cost-effectiveness. By partnering with leading manufacturers such as Company A and Company B, businesses can access high-quality PP sheets tailored to their specific needs, enabling them to innovate, optimize processes, and achieve their goals with confidence. Additionally, understanding pricing considerations and availability of PP sheet rolls empowers businesses to make informed decisions and leverage the full potential of these essential materials in their operations.

Frequently Asked Questions

1. What are polypropylene sheets, and what are their characteristics?

- Polypropylene sheets, often abbreviated as PP sheets, are thermoplastic sheets made from polypropylene resin. They are known for their lightweight nature, high chemical resistance, good impact strength, and excellent processability. PP sheets are widely used in various industries for applications such as packaging, signage, automotive components, and construction.

2. What are the common types of polypropylene sheets available?

- Common types of polypropylene sheets include:

- Homopolymer polypropylene sheets: Made from pure polypropylene resin, these sheets offer high stiffness, heat resistance, and chemical resistance, making them suitable for structural applications.

- Copolymer polypropylene sheets: These sheets are blended with other materials to enhance specific properties such as impact resistance, flexibility, and transparency.

- Recycled polypropylene sheets: Made from recycled polypropylene materials, these sheets offer environmental benefits and are suitable for applications where cost-effectiveness and sustainability are priorities.

3. What are the typical applications of polypropylene sheets?

- Polypropylene sheets find applications in various industries, including:

- Packaging: Used for thermoforming, vacuum forming, and fabrication of packaging trays, containers, clamshells, and blister packs for food, medical, and industrial products.

- Signage and displays: Used for making durable, weather-resistant signs, posters, banners, and point-of-purchase displays for indoor and outdoor advertising.

- Automotive: Used for manufacturing interior trim components, door panels, instrument panels, and bumper fascias due to their lightweight, impact resistance, and chemical resistance.

- Construction: Used for roofing, cladding, glazing, and insulation panels in building and construction applications due to their durability, weatherability, and ease of fabrication.

- Industrial: Used for chemical tanks, ducts, pipes, and liners in industrial applications requiring corrosion resistance, thermal stability, and chemical resistance.

4. How is the price of polypropylene sheets determined?

- The price of polypropylene sheets depends on various factors, including:

- Raw material costs: Prices of polypropylene resin, additives, and other materials used in sheet production impact the overall cost.

- Sheet thickness: Thicker sheets generally cost more than thinner sheets due to increased material usage and manufacturing costs.

- Sheet size and quantity: Larger sheets and bulk orders may have lower unit costs due to economies of scale in production, handling, and transportation.

- Sheet properties: Specialty grades, colors, additives, and surface finishes may affect the price of polypropylene sheets.

- Market demand and supply: Supply-demand dynamics, seasonal variations, and market trends influence pricing fluctuations in the polypropylene sheet market.

Comments

Post a Comment